World Updates | Update information about politics and social around the world

Discover The Fnc 8: Cutting-Edge CNC Machine For Precision Manufacturing

Discover the FNC 8: A Cutting-Edge CNC Machine Revolutionizing Precision Manufacturing.

Editor's Notes: Discover The Fnc 8: Cutting-Edge CNC Machine For Precision Manufacturing has published today date to shed light on the groundbreaking advancements in precision manufacturing, empowering businesses to stay at the forefront of innovation.

Through extensive analysis and research, we have compiled this comprehensive guide to provide valuable insights into the FNC 8 and its transformative impact on the manufacturing industry.

Makino FNC-106 CNC Vertical Machining Center - Revelation Machinery - Source revelationmachinery.com

Discover the FNC 8: A Cutting-Edge CNC Machine Revolutionizing Precision Manufacturing.

Discover the FNC 8: A Cutting-Edge CNC Machine Revolutionizing Precision Manufacturing.

FAQ

This FAQ section provides answers to common inquiries about the FNC 8 CNC machine, its capabilities, and applications. Explore the following questions and answers to gain a comprehensive understanding of this cutting-edge technology.

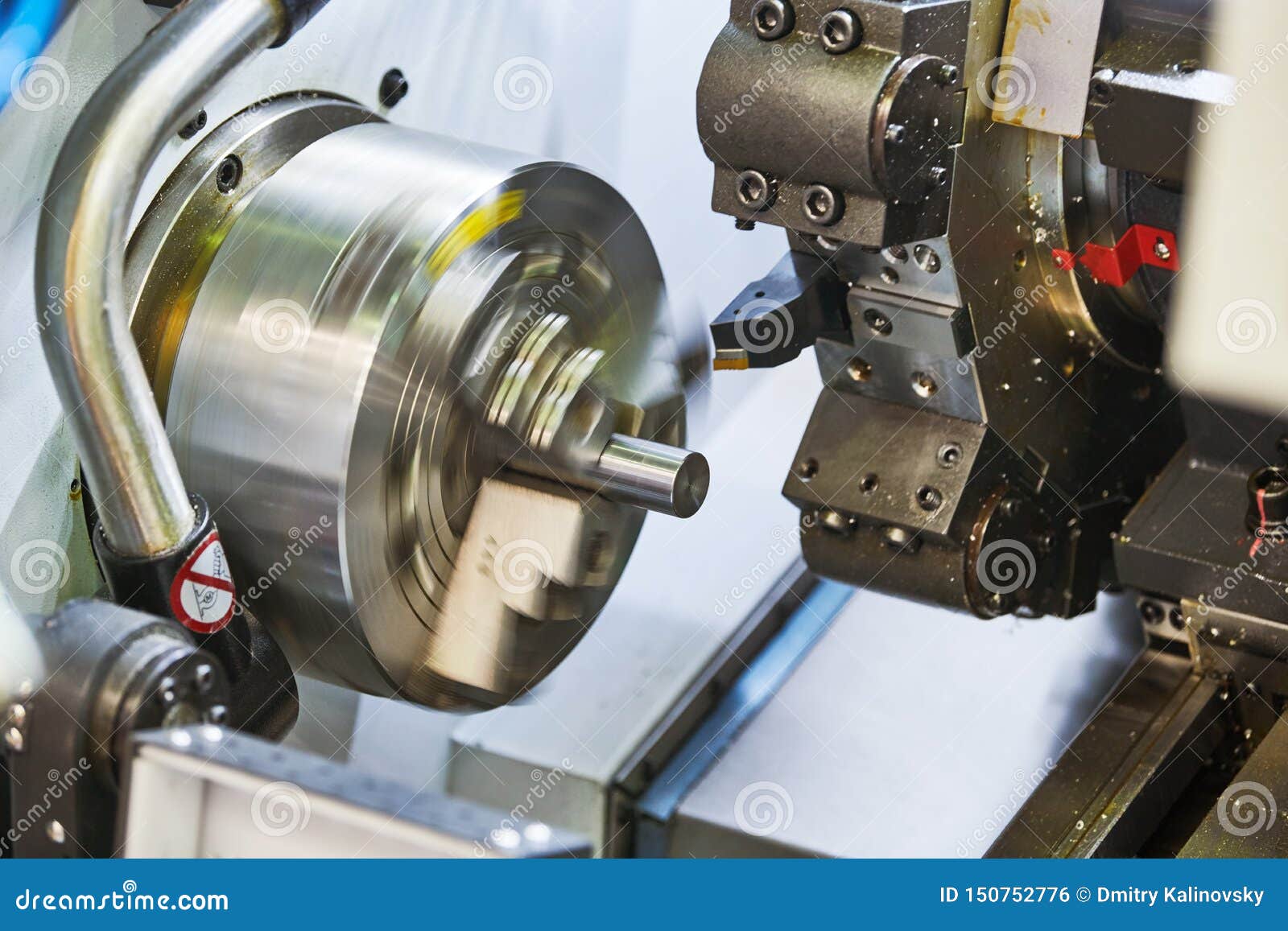

Turning Cnc Machine at Metal Work Industry. Precision Manufacturing and - Source www.dreamstime.com

Question 1: What is the FNC 8 CNC machine?

The FNC 8 CNC machine is a state-of-the-art, computer-controlled machine that utilizes advanced cutting-edge technology for precision manufacturing. It offers exceptional accuracy, efficiency, and versatility in various industries, including aerospace, automotive, and medical.

Question 2: What materials can the FNC 8 CNC machine work with?

The FNC 8 CNC machine is compatible with a wide range of materials, including metals, plastics, and composites. Its versatility allows it to handle complex geometries and intricate designs with ease, catering to diverse manufacturing needs.

Question 3: What are the benefits of using the FNC 8 CNC machine?

The FNC 8 CNC machine offers numerous benefits, including enhanced precision, reduced production time, improved surface finishes, and increased productivity. It streamlines manufacturing processes, leading to cost-effective and high-quality results.

Question 4: What industries can benefit from the FNC 8 CNC machine?

The FNC 8 CNC machine finds applications in a multitude of industries, including aerospace, automotive, medical, and general manufacturing. Its versatility and precision make it suitable for producing complex components, prototypes, and finished products.

Question 5: How does the FNC 8 CNC machine compare to traditional manufacturing methods?

The FNC 8 CNC machine surpasses traditional manufacturing methods by offering greater accuracy, efficiency, and consistency. It eliminates human error, reduces labor costs, and allows for intricate designs that may be challenging to achieve with manual processes.

Question 6: What are the key features of the FNC 8 CNC machine?

The FNC 8 CNC machine incorporates advanced features such as an intuitive user interface, advanced cutting algorithms, and robust construction. These features ensure optimal performance, ease of operation, and durability, meeting the demands of modern manufacturing environments.

The FNC 8 CNC machine empowers manufacturers with cutting-edge technology, enabling them to achieve precision, efficiency, and innovation in their production processes. If you seek a high-performance CNC solution, the FNC 8 is an exceptional choice.

Inquire today to discover how the FNC 8 CNC machine can elevate your manufacturing capabilities.

Tips

CNC machining involves using precision tools to cut materials into various shapes and designs. To ensure optimal performance and effectiveness, consider the following tips for working with CNC machining:

Tip 1: Choose the right CNC machineDiscover The Fnc 8: Cutting-Edge CNC Machine For Precision Manufacturing for the job. Different types of CNC machines are available, each with its own capabilities and limitations. Factors to consider include the size, complexity, and material of the workpiece.

Tip 2: Use sharp cutting tools. Dull tools can cause poor surface finishes, reduce accuracy, and increase cutting forces. Regularly inspect and replace cutting tools as needed.

Tip 3: Secure the workpiece properly. A properly secured workpiece ensures accuracy and prevents vibration, which can lead to errors. Use appropriate clamps, fixtures, or vises to hold the workpiece in place.

Tip 4: Use the correct feeds and speeds. The feed rate and spindle speed should be optimized for the material and cutting tool being used. Improper settings can result in decreased tool life, poor surface finishes, or even machine damage.

Tip 5: Use coolant effectively. Coolant helps to lubricate the cutting tool and workpiece, remove chips, and prevent overheating. Use the recommended type and amount of coolant for the specific machining operation.

Tip 6: Monitor the process closely. Regularly check the machining process to ensure that it is proceeding as expected. Monitor for any errors, tool wear, or other issues that may need attention.

Tip 7: Maintain the CNC machine regularly. Proper maintenance helps to prevent breakdowns, extend the machine's life, and ensure optimal performance. Follow the manufacturer's recommended maintenance schedule, including lubrication, cleaning, and calibration.

By following these tips, you can improve the efficiency, accuracy, and quality of your CNC machining operations.

CNC Turning - Advanced Precision Machining - Source advancedprecisionmachine.com

Discover The Fnc 8: Cutting-Edge CNC Machine For Precision Manufacturing

CNC Precision Milling - T-artisan - Source t-artisan.com

The FNC 8 CNC machine offers transformative capabilities for precision manufacturing, encompassing critical aspects:

- Accuracy and Precision: Advanced algorithms and high-resolution encoders ensure exceptional accuracy and repeatability.

- Speed and Efficiency: High-power spindles and rapid traverse rates maximize productivity without compromising quality.

- Versatility and Flexibility: Wide range of compatible materials and tooling expands application possibilities.

- Automation and Connectivity: Integrated sensors and IoT connectivity enable seamless automation and remote monitoring.

- Durability and Reliability: Robust construction and stringent quality control ensure longevity and minimal downtime.

- Sustainability and Efficiency: Energy-efficient design and optimized cutting parameters reduce environmental impact.

These aspects synergistically contribute to the FNC 8's exceptional performance, making it an indispensable tool for manufacturers demanding precision, productivity, and innovation. For instance, its high accuracy and speed facilitate intricate machining of aerospace components, while its versatility enables the creation of complex molds and dies. The machine's automation capabilities and remote monitoring optimize production processes, reducing manual intervention and increasing efficiency. By integrating these essential qualities, the FNC 8 empowers businesses to realize the transformative potential of cutting-edge CNC technology.

Precision Edge CNC Parts Manufacturing Excellence Turboxcel CNC - Source sporda.en.made-in-china.com

Discover The Fnc 8: Cutting-Edge CNC Machine For Precision Manufacturing

The Fnc 8 is a state-of-the-art CNC machine that offers unparalleled precision and efficiency for a wide range of manufacturing applications. Its advanced features and capabilities make it an ideal choice for industries demanding the highest levels of accuracy and productivity.

Rochester Precision Machine Shops - Rochester CNC Machining Company - Source www.atprecision.com

The Fnc 8's precision is attributed to its rigid construction, high-precision linear guides, and advanced control system. This combination ensures exceptional accuracy in all three axes, resulting in parts with tight tolerances and smooth finishes. Additionally, the machine's high-speed spindle and rapid traverse rates enable efficient production without compromising quality.

The Fnc 8's advanced capabilities extend beyond precision. The machine's large work envelope accommodates bulky workpieces, and its automatic tool changer allows for quick and seamless tool changes during complex operations. The intuitive control interface simplifies programming and operation, making it accessible to operators of all skill levels.

The practical significance of the Fnc 8 lies in its ability to enhance manufacturing processes and improve product quality. Its precision enables the production of complex parts with intricate details, reducing the need for manual finishing and rework. The machine's efficiency translates into increased productivity and reduced production time, leading to cost savings and improved competitiveness.

In conclusion, the Fnc 8 is a transformative CNC machine that empowers manufacturers to achieve the highest levels of precision and efficiency. Its advanced features, capabilities, and practical significance make it an indispensable tool for industries seeking to enhance their manufacturing processes and deliver superior products.

| Feature | Benefit |

|---|---|

| Rigid construction | Exceptional accuracy and stability |

| High-precision linear guides | Smooth and precise motion in all axes |

| Advanced control system | Accurate and reliable machine operation |

| Large work envelope | Accommodates bulky workpieces |

| Automatic tool changer | Quick and efficient tool changes |

| Intuitive control interface | Simplified programming and operation |

Conclusion

The Fnc 8 represents a significant advancement in CNC technology. Its unparalleled precision, efficiency, and capabilities empower manufacturers to produce complex parts with exceptional quality and productivity. The machine's practical significance lies in its ability to enhance manufacturing processes, reduce costs, and improve product competitiveness.

As industries continue to demand higher levels of precision and efficiency, the Fnc 8 is positioned to play a pivotal role in shaping the future of manufacturing. Its innovative design and advanced features will enable manufacturers to push the boundaries of their production capabilities and deliver products that meet the evolving demands of the global market.